History

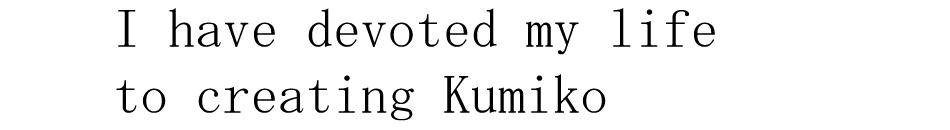

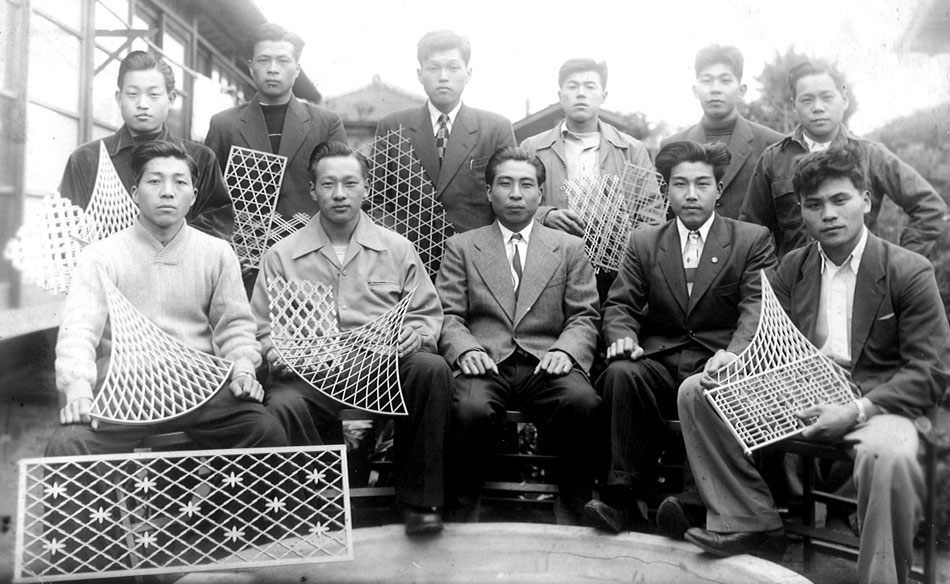

My father, Toshio Tanihata, who died at 73 in March 2006, started his training in Kumiko in 1956 when he was 23. After working at the Karinogi factory in Toyama for 5 years, he was advised to take up fine handwork so joined the Fitting Woodwork Research Centre at Urawa (Saitama).

At that time, he should have started training in Kumiko straight after finishing junior high school. However, from the time he did start in his late twenties, he devoted his life to Kumiko. After returning home to Toyama at the age of 26 in 1959, he started the Tanihata Kumiko Company. Later on he met my mother and they married.

Toshio Tanihata started business with nothing – no property, car or machines. “I carried our products by handcart or public bus, which was tiring, especially when I had to get onto crowded buses with my products. I used to sleep on wood shavings because I was too tired to move to my bed. It was warmer than I expeceted! I couldn’t borrow money from banks because I was too young to be trusted.” My father used to say, “Remember those who gave us our hands. I even tied you to a pillar in the factory so you couldn’t go anywhere.” Laughingly, my mother said, “We might have been reported for child abuse if it happened now!” Having experienced this conditioning throughout my childhood, it seemed natural for me take over my father’s business in the future.

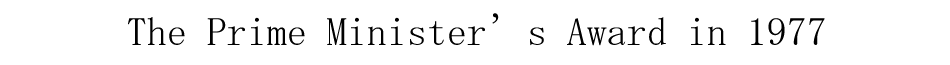

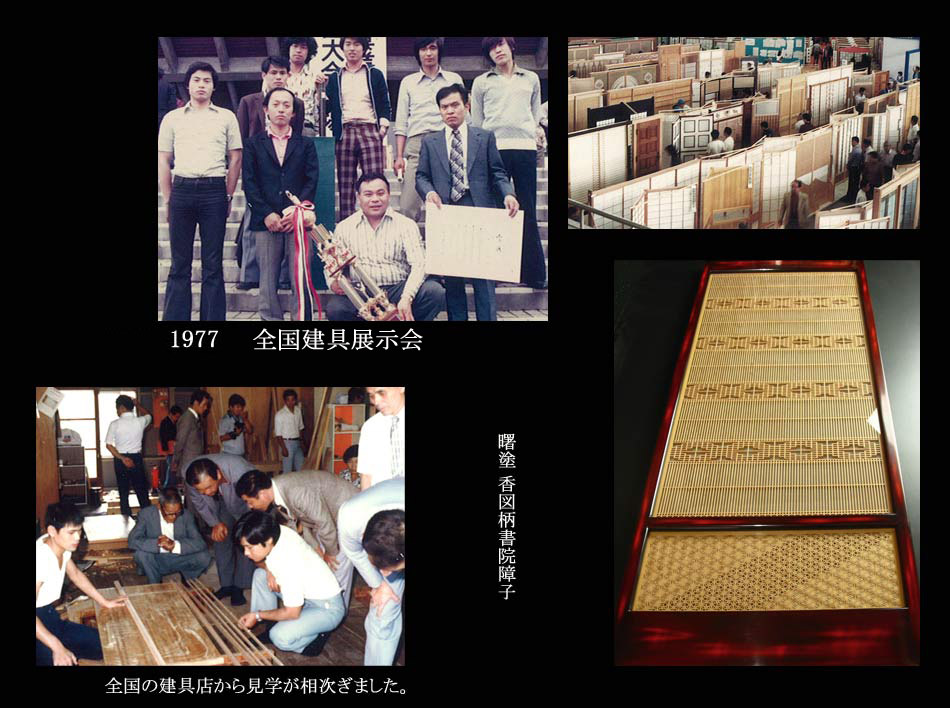

Things started to improve when, at the age of 44, my father received important recognition in the form of the Prime Minister’s Award at the National Fitting Exhibition. He was the first person to receive the award in the Tohoku area, and the Tanihata name became known across Japan. Kumiko sales picked up. Our skill also developed because of demand from home owners in an area where there was a high level of home ownership. “We were too busy to follow up on all orders. And it was hard to decline requests for apprenticeships,” my father said. Twenty-five craftsmen who used to work as trainees with Tanihata, now have their own businesses.

Although we have no salesperson among our twenty staff members, we have been successful in finding new customers through introductions from existing customers. Only recently have I understood my father”s spirit of craftsmanship, conveyed by his words, “As Kumiko craftsmen, we can succeed in business despite being looked down upon by architects and builders.”

In the 1990s, when sales were declining, I decided to return to my hometown to take over the business. In additon to a national economic recession having struck our business, the most serious reason for the decline in sales was the fact that the younger generation was tending away from traditional Japanese style rooms towards a preference for Western style dwellings with wood flooring, curtains and sofas. While traditional style homes still existed in Hokuriu, Western style housing was already common in the Tokyo area.

In this situation, the market was favourable for developers and contractors selling houses with Western style interiors, built at a lower cost than expensive traditional Japanese homes for which there was declining demand. This led to a slump in Kumiko sales and concern about becoming bankrupt. In this difficult situation, with no sales staff, and carrying a stock of new products – room dividers suitable for westernised homes – I had to go and sell to bigger companies, including department and furniture stores, DIY and online shops and builders. I thought this was the only way to overcome the serious downturn in sales.

Travelling between Tokyo, Osaka and my hometown Toyama, and working long hours over three years, was taking a toll on my health. But I was driven by a commitment to protect my company from bankruptcy.

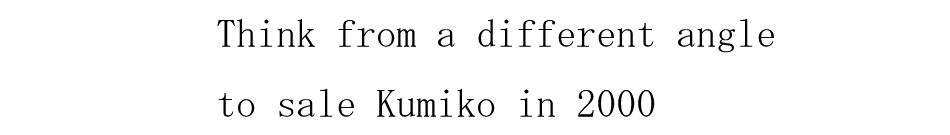

When I realized that I couldn’t force myself to keep working as I had at our company sales forever after nearly breaking down, I launched our website and focused on sales through the Internet in December 2000. Nowadays, online sales of building materials is common, but the Internet was still in its infancy back then. I still remember that many of our clients told us. “There is no way you can sell these products on the Internet.”

In fact, there were many days when sales did not increase in the beginning. But the numbers gradually started to rise on the Internet sales around 2002. In October 2007, we received the “METI Award for 100 Best IT Management Companies”. With our well established technical skills at the center, we went on to refine our IT and design skills, and gradually shaped our management style by changing “where to sell”, “how to sell”, and “how to create”.

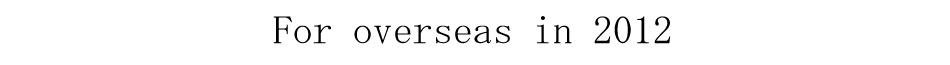

As the popularity of Kumiko increased in Japan, the number of inquiries for Kumiko products from overseas gradually increased.

In 2012, we participated in the New York International Furniture Exhibition, the first overseas exhibition for Tanihata. We were surprised by the positive responses we received, greatly exceeding our expectations, but at the same time, we were keenly aware of our shortcomings. Immediately after returning to Japan, we lanched an English website and English brochure, and began to expand our business for overseas markets.

We have delivered more and more products to the facilities of foreign companies such as the Ritz-Carlton, Apple, Twitter, Hermes, Starbucks, etc., and guests from overseas have continued to come to visit our factory directly in Toyama.

I myself also have had more opportunities to go abroad; Italy, Germany, France, Korea, Hong Kong, and Singapore, to name but a few. I did not go abroad alone, but together with the craftsmen, and we are continuing to think about the direction of Japanese craftsmanship and trying different new things. These days, our overseas sales have reached nearly 20% of our total sales.

We have received orders from customers both in Japan and overseas, and received a plethora of comments; “Japanese techniques and designs are wonderful.”, “This reminds me of the spirit of cherishing things,” and “This kind of Japanese technique must be preserved.”

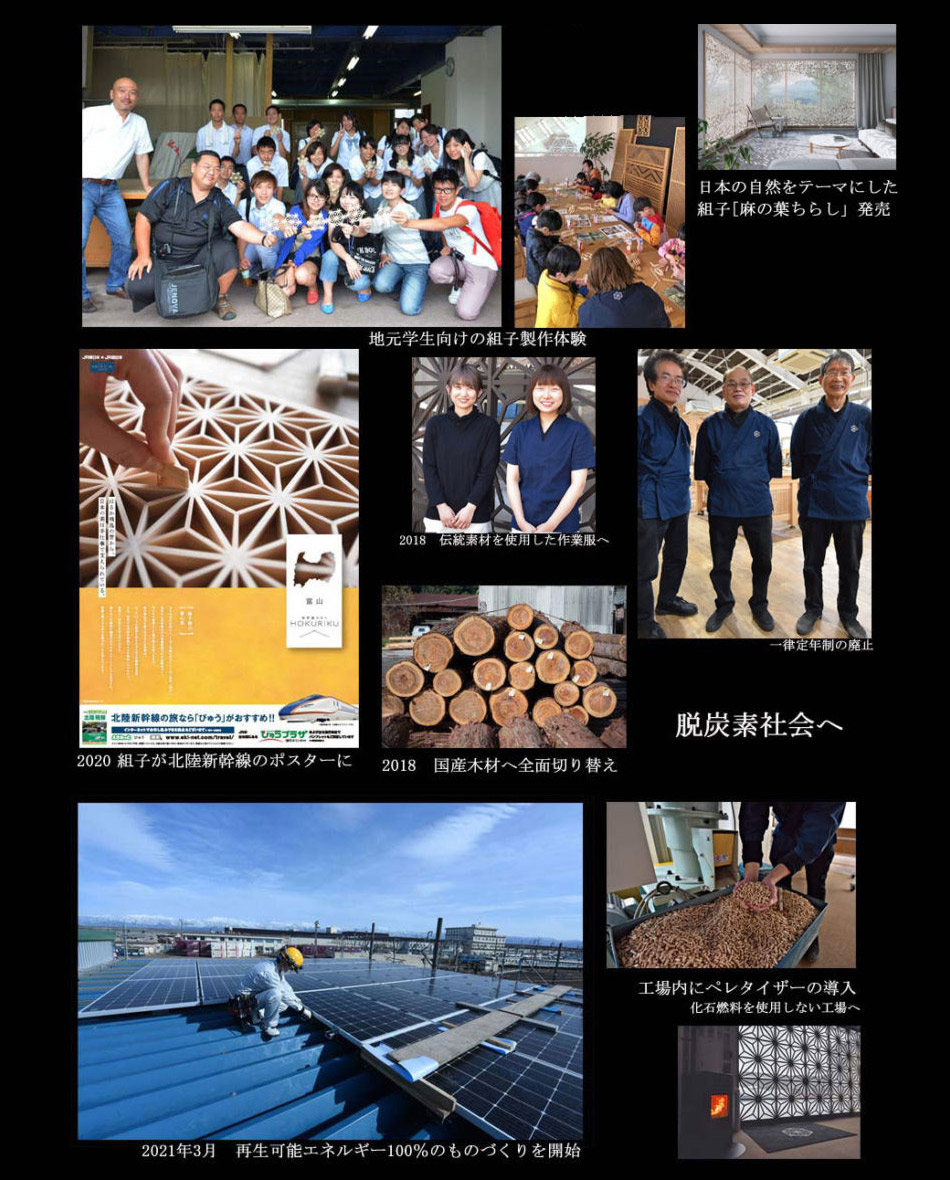

About 30 years have passed since we had experienced a tough times with sales, and we truly feel that our Kumiko production has been made possible thanks to the support of many people, business partners, local communities, and nature itself. We also want to give back what we have gained through making our Kumiko to the people and communities who have helped us grow.

In January 2016, we at Tanihata set up our first management philosophy. It was not something we “thought up” per se, but rather something that came naturally from within ourselves.

For the children of the next generation, we would like to work as craftsmen who strive not to forget the important things that Japanese people have cultivated over our illustrious history, and who boldly work to take on challenges with determination.

Nobuo Tanihata

Book [Sharing our Spirit of Craftsmanship with the World]

Click here